As is well known, fluororesins represented by polytetrafluoroethylene (PTFE) have properties such as pollution resistance, non-stickiness, acid resistance, heat resistance, and low friction, which are widely known to be extremely useful in industry. However, this resin has high crystallinity and cannot form a transparent film. Moreover, film formation requires high heat, making it unsuitable for anti-soiling applications that require transparency.

In recent years, various coating agents that can form transparent films at room temperature using the characteristics of fluororesins have been developed and put into practical use. Next, we will introduce a fluorine-based coating agent that can be used for anti-soiling and reducing fingerprint adhesion on various materials.

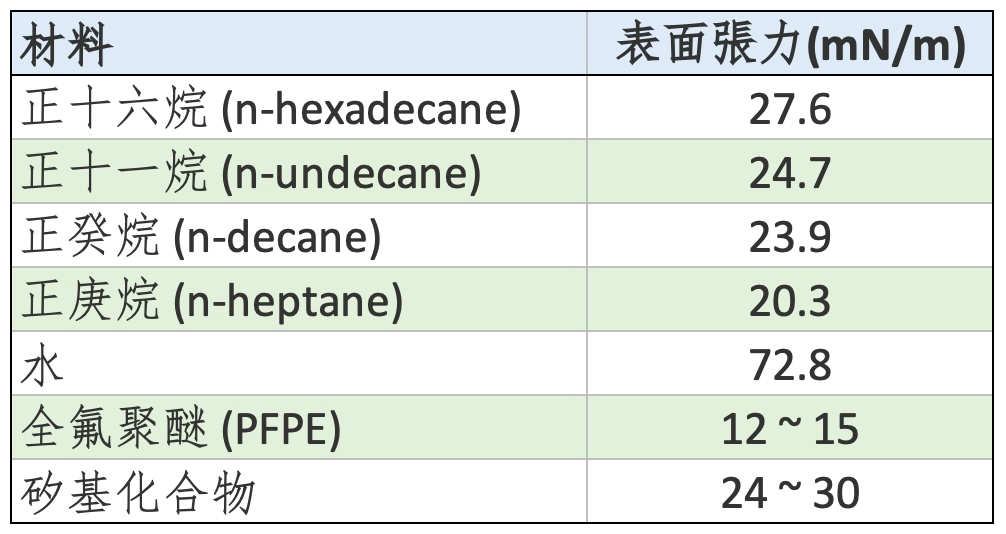

1. Anti-soiling mechanism of fluorine-based coating agents Fluorides are a group of substances with the lowest surface tension in solid materials, with a surface tension as low as about 6-30 mN/m. Liquid stains, such as fingerprints, sebum stains, and water stains, adhere to the surface due to the attractive forces between the stain components and the surface molecules of the substrate. By coating the substrate with a fluorine-based coating agent, the fluorine resin covering the surface can significantly reduce the surface tension of the substrate, thereby reducing the adhesion of dirt. The ease of wiping off dirt with a cloth can clearly demonstrate this effect. Roughly speaking, the ease of wiping depends on the adhesion of the dirt to the substrate surface (W3, yellow arrow in Fig-1), the attraction between the fiber and the dirt (liquid) (W1, dark yellow in Fig-1), and the balance of these three forces including gravity (W2, green) Due to the silane coupling reaction between the coating components and inorganic materials, these coatings exhibit excellent adhesion and abrasion resistance. Additionally, since the thickness of the monomolecular layer is approximately 10-20 nm, it is invisible to the naked eye and does not damage the appearance or optical properties of the coated substrate, nor does it cause scratches. Furthermore, even if the coating components peel off due to wear or aging, this peeling occurs at the molecular layer level, which is not visible to the naked eye. Therefore, it will not lead to an unsightly appearance due to peeling like conventional coatings, nor will it damage the appearance value of the coated object. From these perspectives, it can be said to be the most suitable coating agent for preventing fingerprints. However, if the surface lacks hydroxyl groups (-OH) or carboxyl groups (-COOH) like typical plastics, this coupling reaction will not occur, and the coating components cannot bond tightly. In such cases, it is necessary to use polysilazane or tetramethoxysilane as a pretreatment agent to form an inorganic glass-like (silica) film on the surface of the substrate before applying this coating agent. 2-3 UV-Curable Anti-soiling Coatings 3. Evaluation of Wear Resistance of Anti-soiling Fluorine Coatings 3-1 Anti-soiling Performance Evaluation Table-2 Surface tension of various substances 3-1-1 Measurement of Dynamic Contact Angle Using the Sliding Method 3-2 Wear Resistance Evaluation 3-2-1 Example of Evaluation Method Used by Panel Manufacturers 3-2-3 Simple Test (Oil-Based Ink Test) It is important to note that using human fingerprints to evaluate stain resistance is quite unstable because even in the same person, the secretion status (including its components) can change instantly, making it difficult to obtain an accurate assessment. Here, we use an oil-based pen as an alternative to fingerprint components. Additionally, it goes without saying that it is best to use the same brand of oil-based pen and tissue. 3-3 Test Examples and Their Criteria 3-3-1 Evaluation Method Example Combining Sliding Contact Angle Method with Friction Test 3-3-1-2. Test Conditions 3-3-1-3. Friction Conditions 3-3-2 Simple Anti-soiling Test Combined with Sliding Contact Angle Test Method 3-3-3 Evaluation Criteria The evaluation criteria vary depending on the application of the product and the quality standards of the user. Some representative standards are discussed below. 3-3-3-1. Evaluation Criteria for Contact Angle 3-3-3-2. Evaluation Criteria for Simple Tests

Figure-1 Anti-soiling Mechanism

If W1 is significantly greater than the sum of W3 and W2, the dirt components will be attracted to the fiber side, making it easier to remove the dirt from the substrate surface. In other words, if the surface tension of the adhering surface is lower, W3 is smaller, and anti-soiling effect can be achieved.

2. Types and Characteristics of Anti-soiling Fluorine Coatings There are roughly two types of fluorine coatings used to reduce fingerprint adhesion and prevent soiling. Here is a brief introduction to their characteristics.

2-1 Silane Coupling Type Anti-soiling Coatings These coatings contain organofluorine groups and are based on silane coupling agents. After application, they undergo a silane coupling reaction to bond with inorganic materials such as glass and metal, forming a monomolecular fluoride layer on the surface.

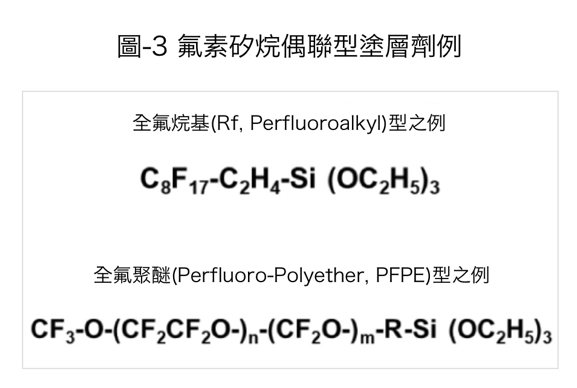

When this type of coating agent first appeared on the market, it used silane-coupled fluororesins with perfluoroalkyl groups such as perfluorooctyl or perfluorohexyl (Rf groups). In recent years, silane-coupled fluororesins with perfluoropolyether (PFPE) groups have also emerged. In terms of performance, compared to Rf-based products with a water contact angle of 117°, PFPE-based products have a water contact angle of 110°, which may seem to indicate lower performance. However, in terms of anti-soiling performance and slickness, PFPE-based products outperform Rf-based products. Coating agents with PFPE groups have gradually become mainstream.

PFPE-based coatings can be applied using conventional coating methods such as spraying and immersion (wet processes). Coatings with a molecular weight around 4000 can also be applied using vacuum deposition (dry process) for surface treatment. Coatings processed by vacuum deposition are more durable than those processed by wet processes, so they are often used for fingerprint and anti-soiling treatment of eyeglass lenses and touch screen displays. However, the manufacturing cost of this method is higher, so there is a gradual shift towards more cost-effective wet coatings, especially through the widespread use of spray coating machines.

2-2 Metal Anti-soiling Coatings

Similar to the aforementioned silane-coupled type, this is a reactive anti-soiling coating agent with a PFPE base that reacts with and adheres to the metal surface. The silane-coupled type introduced earlier also has a structure that reacts with and adheres to the metal surface, but it has higher adhesion and forms a wear-resistant, anti-soiling surface after application. Like the silane-coupled anti-soiling coating agents mentioned earlier, the thickness of this coating film is 10-20 nanometers, which is invisible to the naked eye, so it does not change the appearance of the material and can exhibit anti-soiling performance. Photo-1 shows the situation of a faucet used in a bathroom with the coating applied on its right half, after one month of use and cleaning off the dirt with a cloth. Usually, limescale and detergent scum that cannot be removed by wiping alone can be easily removed from the surface coated with this coating.

This type of coating can be applied to resin-molded metal molds for releasing actions. It not only reduces the surface tension of the mold surface but also, with a friction coefficient below 0.09, can exhibit consistently good releasing performance. Additionally, with a thickness of 10-20 nm, it can faithfully reproduce fine structures from nanometers to micrometers on the mold surface, such as nanoimprinting. Moreover, since the components of the release coating do not adhere to the workpiece, there is no need to clean the workpiece after releasing, greatly improving productivity.

There are two types of UV-curable coatings: one is an additive type that can be added to free radical polymerization UV-curable resins, and the other is a type that is already mixed in UV-curable resins or hardeners and can be used directly. Both types cure by UV irradiation; their characteristic is fast curing speed, making them suitable for high-speed processing of plastic films using roll-to-roll methods. The curing reaction is a cross-linking reaction caused by free radical polymerization, which is inhibited by oxygen. Therefore, it needs to be exposed under nitrogen or with a thicker film under normal conditions to isolate oxygen. Additionally, the appearance after application is typically glossy. Although the static contact angle of this coating agent is similar to other types of coating agents, its surface structure is not completely covered by fluorides, so its fingerprint resistance is not as good as the aforementioned reactive types. Table-1 compares our UV-curable resin anti-soiling additive with the silane-coupled anti-soiling coating agent mentioned earlier.

To assess adhesion and durability from the practical perspective of anti-soiling performance and reducing fingerprint adhesion, it is common to measure the contact angle after applying wear using a friction tester. This section will introduce these evaluation methods for anti-soiling coatings. Additionally, scratch tests and tape tests evaluate the adhesion of coatings by observing the difference in adhesive force between the tape and the film. These results are influenced by the surface tension of the coating and are therefore not suitable for adhesion tests of water and oil repellent agents or anti-soiling coatings, so this chapter omits them.

Traditionally, the static contact angle of water or oil has been used as a general indicator of anti-soiling and anti-fingerprint performance. Recently, some touch panel manufacturers have evaluated fingerprint resistance solely based on the static contact angle of water. However, relying solely on the contact angle of water cannot provide an effective evaluation of adhesion to sebum stains or fingerprint adhesion (reduction of fingerprint adhesion, ease of wiping fingerprints). This is because the surface tension of water is too high compared to the main component of fingerprints, which is sebum. For example, when a silicon-based compound is applied to the surface of a substrate (surface tension of 24 mN/m), it can effectively repel water (72.8 mN/m), achieving a static contact angle of over 100°. However, it cannot repel oily components such as wax-based substances with a similar surface tension (22 mN/m). It can be seen that silicon has no effect on preventing fingerprint adhesion, and it can also be seen that the static contact angle of water is not suitable for evaluating the performance of resisting fingerprint adhesion.

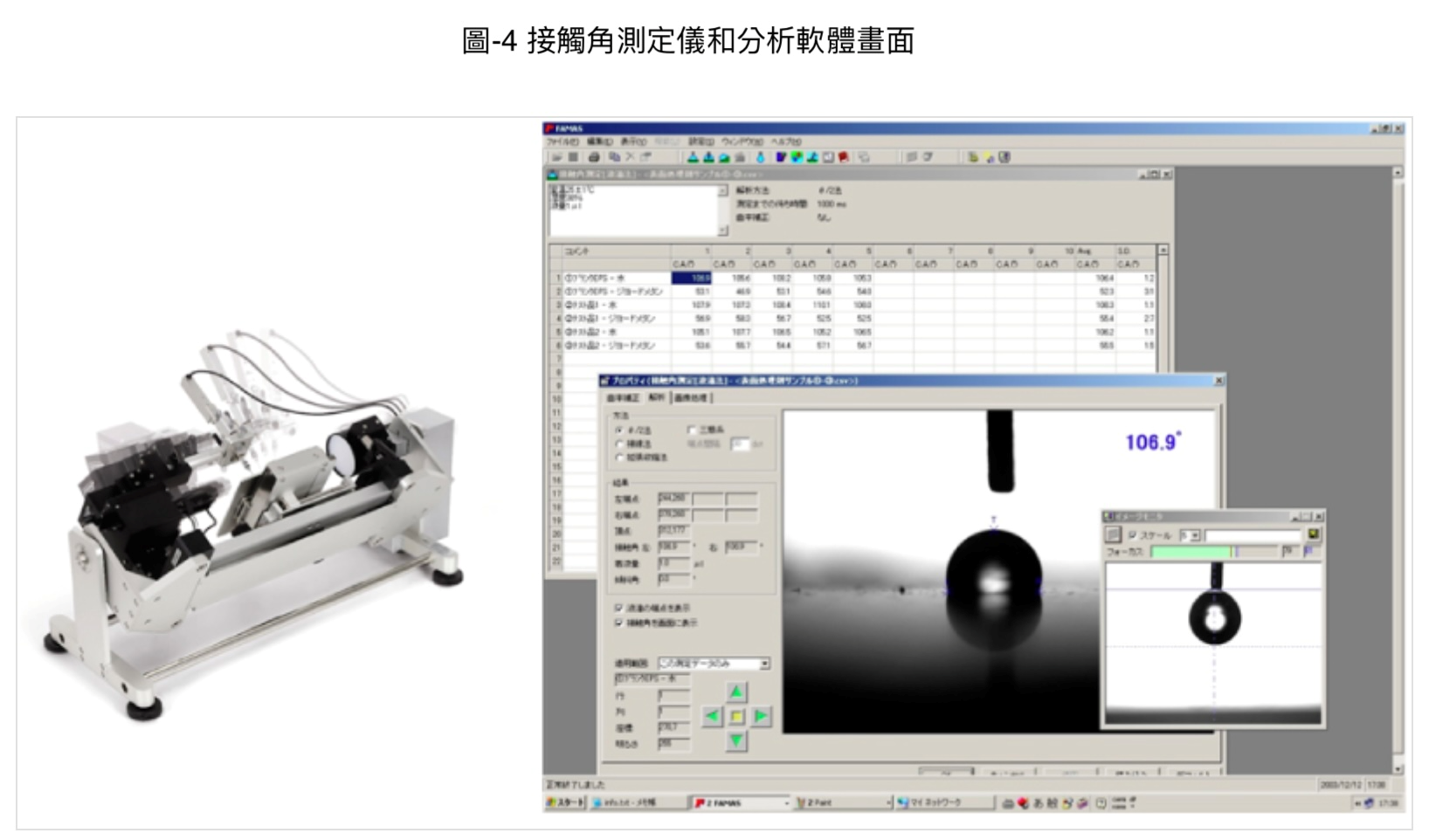

For contact angle measurements, it is more appropriate to use substances similar to fingerprint components, such as hexadecane, oleic acid, and triolein. Patent No. 3745317 describes other examples of artificial fingerprint liquids, and JIS-K2246 also mentions artificial fingerprint liquids. However, these are used to evaluate corrosion resistance and are not suitable for evaluating anti-soiling performance because they do not contain any oily components. Additionally, in cases where the functionality of anti-soiling coatings is reduced due to wear, measuring with oily components sometimes yields a high static contact angle that is not related to anti-soiling performance. This situation is also commonly observed. In daily life, the adhesion mechanism of fingerprints to objects in actual use is always accompanied by movement, so it is necessary to evaluate from the perspective of the adhesion energy of dirt to the adhering surface. For this reason, using the sliding method to measure the dynamic contact angle is more suitable than measuring the static contact angle. Of course, when measuring the dynamic contact angle, oily components should be used instead of water. In actual measurements of the dynamic contact angle, it is often observed that there is a deviation of several degrees. This is due to changes in the surface of the object being measured (wetting of the liquid contact surface or flipping of the polymer) and the surrounding environment (temperature, humidity, airflow, vibration). Therefore, it is best to perform approximately 5 to 8 measurements on the same sample surface to obtain the average value and deviation.

Using the sliding method to measure the dynamic contact angle is done with a measurement stage tilted at 1°. The sliding angle when the droplet starts to slide, the advancing contact angle when the droplet is sliding, and the receding contact angle on the back of the droplet are measured using specialized high-speed image processing. By calculating these three contact angles and the volume of the droplet, the adhesion energy of the droplet to the material surface can be determined. The values of the sliding angle and the receding contact angle are highly correlated with fingerprint adhesion. The smaller the sliding angle, the lower the adhesion energy, and the larger the receding contact angle, the lower the surface tension. Therefore, if these numbers perform well, it can be said to have good anti-soiling properties, especially high fingerprint removal performance.

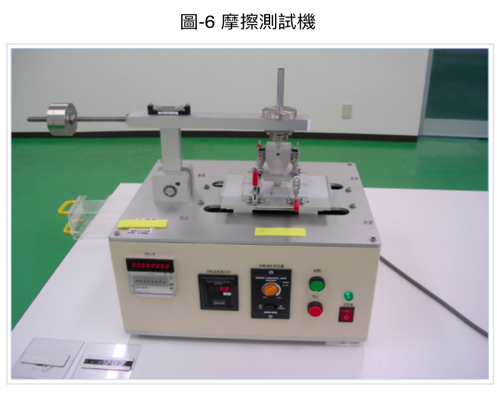

The general method for evaluating wear resistance is to use a friction tester to conduct wear tests and assess wear resistance by comparing the contact angles before and after friction. A typical friction tester, as shown in Figure-6, applies mechanical friction by sliding horizontally with weight applied from above. Since dynamic contact angle measurement was discussed in the previous section, this section will focus on friction.

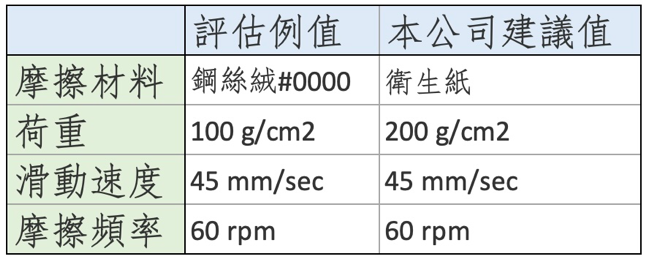

Some panel manufacturers use the friction conditions in the table below for friction testing, and then assess the wear resistance based on the static contact angle of water. With this evaluation method, using steel wool as the abrasive material can sometimes result in the anti-soiling layer being scraped off along with the substrate, leading to different measurement points. Additionally, it is very difficult to set up steel wool on the friction tester, and it is not easy to maintain the smoothness of the friction surface, causing the load to concentrate locally and resulting in inaccurate friction results. The smoothness of the surface depends on the skill of the person setting it up, making it very difficult to ensure consistent data. As discussed earlier, it is difficult to accurately determine the deterioration of anti-soiling properties based solely on the static contact angle of water. For these reasons, this does not seem to be an ideal testing method.

Table-3 Friction Test Conditions

3-2-2 Our Recommendations

Our company conducts durability friction tests based on custom standards (Table 3). Since most consumers actually use tissues or clothing to wipe off dirt, we use tissues as the friction material. Under these conditions, the components of the anti-soiling coating that adhere to the tissue may partially re-adhere to the surface being wiped. To reduce the impact of this effect and prevent tissue damage, the tissue must be replaced every 1000 friction cycles. Additionally, for relative comparative evaluations, the load can be set to 1 kg/cm² to shorten the test time. Furthermore, contact angles are measured using hexadecane to determine the dynamic contact angle. The results of these two tests are used to evaluate the anti-soiling coating.

Dynamic contact angle meters require high-speed image processing and are expensive equipment. Here, we introduce an inexpensive and simple method to evaluate stain resistance without using this equipment. The test steps are as follows:

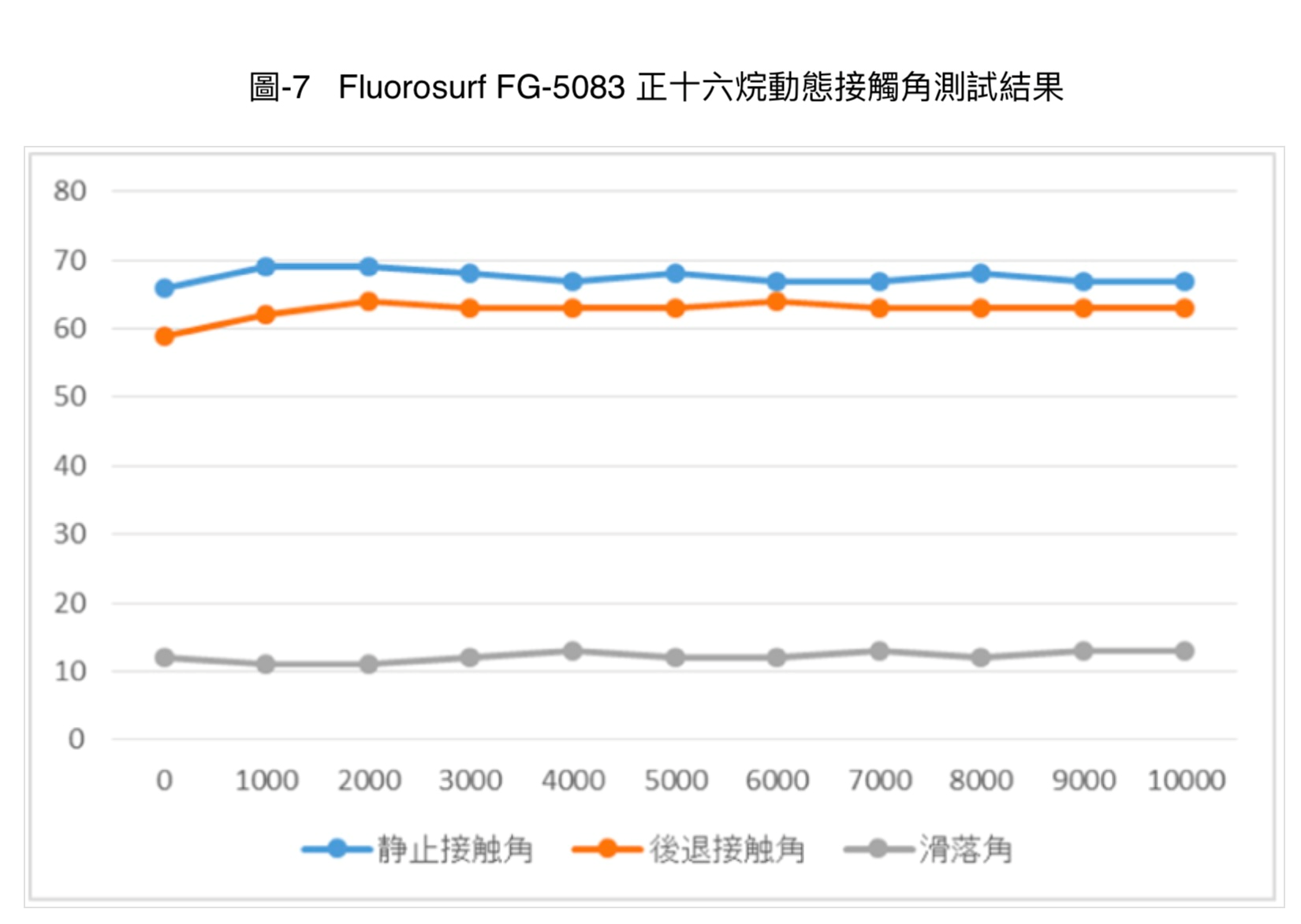

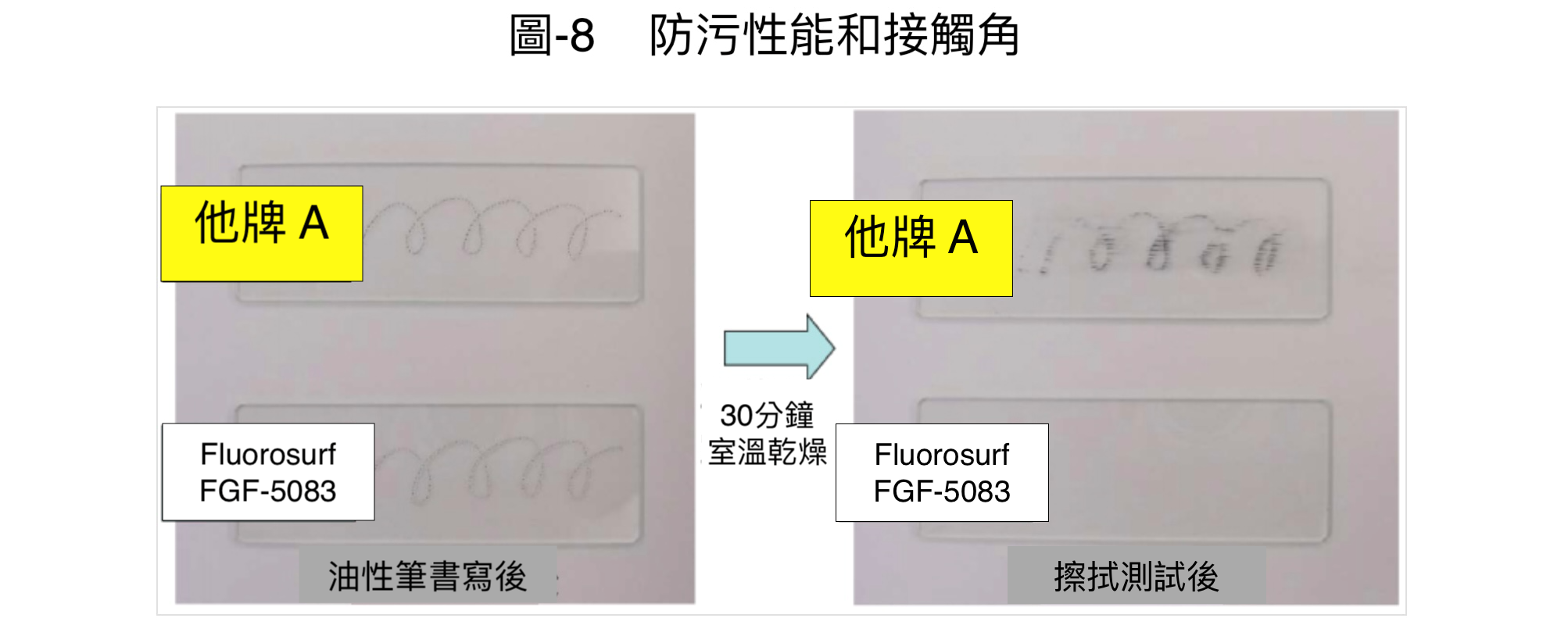

Here, we introduce a test example using hexadecane, which is the most common method for evaluating the dynamic contact angle. We combine the wear resistance test of our company's product Fluorosurf FG-5083 with the static contact angle, the rear contact angle, and the sliding angle of hexadecane. In Figure-7, the vertical axis represents the various angles, and the horizontal axis represents the number of frictions. Please refer to the next section for test conditions and data. From this evaluation result, it can be seen that the product has good wear resistance. Additionally, Figure-8 shows a simple test and the dynamic contact angle of the fluorosurfactant anti-soiling coating agent (Fluorosurf FG-5083 series) based on perfluoropolyether (PFPE) compared to the perfluoroalkyl (Rf) type fluorosurfactant anti-soiling coating agent. From this evaluation result, it can be seen that the static contact angle is not an indicator of anti-soiling performance, and there is a correlation between the dynamic contact angle and anti-soiling performance.

3-3-1-1. Material Sample Preparation Conditions

The materials used are tempered glass for touch screens or microscope slides. For tempered glass, the results may vary depending on the manufacturer, so please try to standardize. Pre-treatment with acetone and hexane cleaning before coating. Apply each anti-soiling coating agent by immersion or spraying. Results may vary depending on the coating method and conditions (coating amount or immersion pulling speed), so they should be standardized. Heat curing at 100°C and 60% humidity for 60 minutes.

(1) Measure the sliding contact angle of the above glass sample using a dynamic contact angle meter.

(2) Use hexadecane for the test, and the volume of the droplet should be 5μl.

(3) Measure 5 points on the glass sample and calculate the average.

(4) Measure the sliding contact angle before friction as the initial value.

(5) Under the following friction conditions, measure the sliding contact angle after the specified number of frictions and compare.

(1) Friction material: tissue paper (folded in quarters).

(2) Load: 200g/cm²

(3) Friction speed: 45mm/sec, cycle 1/sec

(4) Replace the tissue paper with a new one every 1000 uses.

The sample preparation method is the same as the sliding contact angle method described above. The conditions for the simple anti-soiling test are as follows.

(1) Write on the test surface with an oil-based pen and observe the writing state. (It is best to have photo documentation.)

(2) Air dry for 30 minutes. (The drying time will affect the test results, so the time should be consistent.)

(3) Using the same conditions as the aforementioned friction test, use the friction tester to friction back and forth four times.

(4) Observe the remaining ink. (It is best to have photo documentation.)

The evaluation criteria for contact angles and anti-soiling properties are as follows. If the static contact angle measured with hexadecane is less than 50°, it is difficult to say that it has oil-repellent properties. The smaller the sliding angle, the better. If a slope of 30° or greater is required, the anti-soiling properties are usually poor; however, as mentioned earlier, the results will vary depending on the type of test liquid and the size of the droplet, so caution is necessary. A performance where the difference between the rear contact angle and the static contact angle is small is preferable; if this difference is 10° or greater, the anti-soiling performance is usually poor.

Basically, it is evaluated based on the amount of residual oil-based ink, but if the ink can be directly drawn on the test piece during drawing, or if there is still ink residue on the surface after wiping with the friction tester four times, it can be considered as failing.