Fluororesins, represented by polytetrafluoroethylene (PTFE), possess low surface energy and exhibit unique properties such as stain resistance, non-stick characteristics, acid resistance, heat resistance, and low friction, making them highly useful and well-known in industrial applications. However, due to the inability of these resins to form transparent coatings and the requirement for high heat to form a film, they cannot be used for the anti-stain function of transparent resins.

In recent years, taking advantage of the unique properties of these fluororesins, various coating agents that can form transparent films at room temperature have been developed and put into practical use. Next, we will specifically introduce fluorine coating agents that can be used for anti-stain or fingerprint reduction on plastic films or transparent resins.

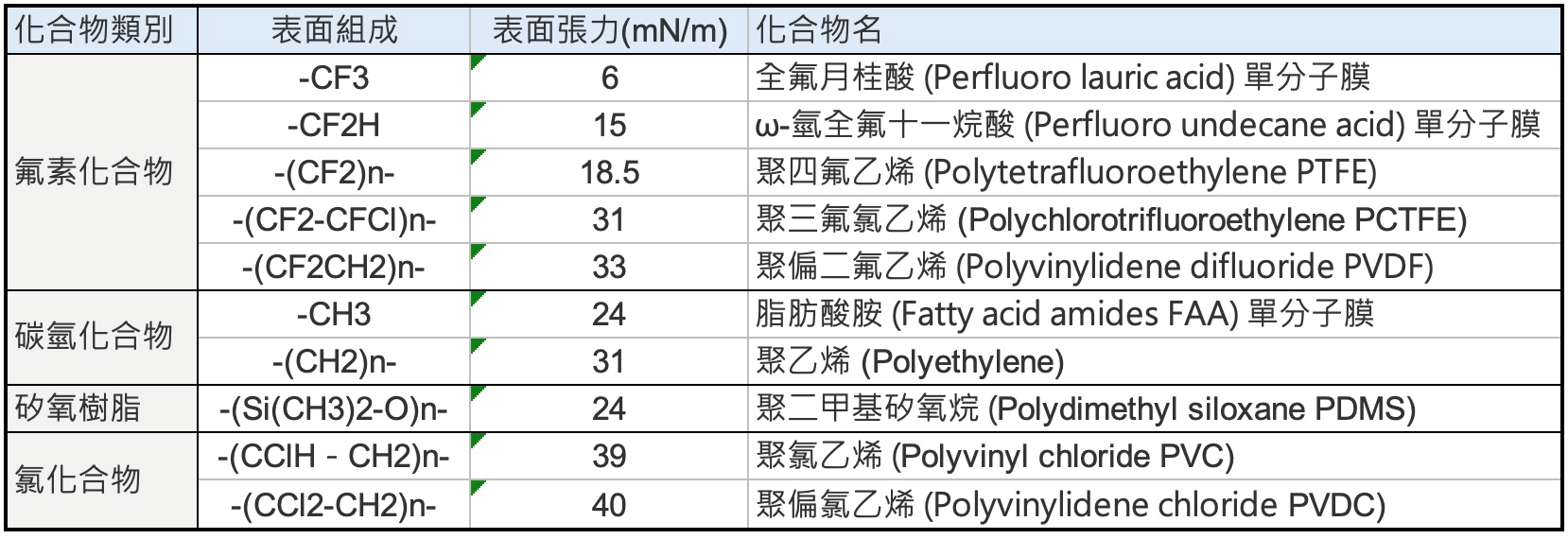

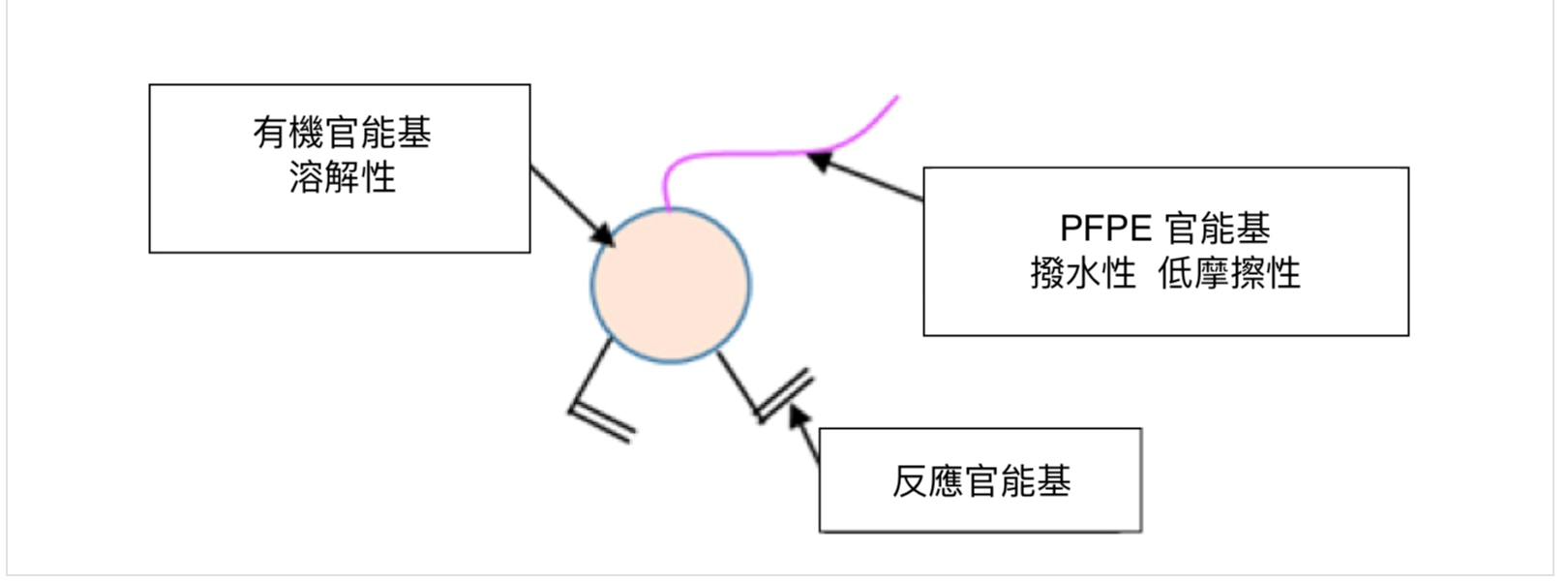

1. Mechanism of anti-stain fluorine coating agents As shown in Table 1, fluorinated compounds are a group of substances with the lowest surface tension among solid materials, with a surface tension of approximately 6-30 mN/m.

Stains adhering to the surface of resins, such as fingerprints, sebum stains, and water scales, are wet stains from liquids. They adhere to the resin surface due to intermolecular forces (= surface tension) generated by the attraction between the molecules of the stain components and the resin surface. Although the surface tension of resins is inherently lower than that of inorganic compounds, the not-so-low surface tension combined with the oleophilic nature of the resin components causes oil stains to stick. By using fluorine coating agents, the surface tension of the resin surface can be significantly reduced, thereby reducing the adhesion of these stains. This effect is particularly noticeable in the ease of wiping off stains with a fiber cloth.

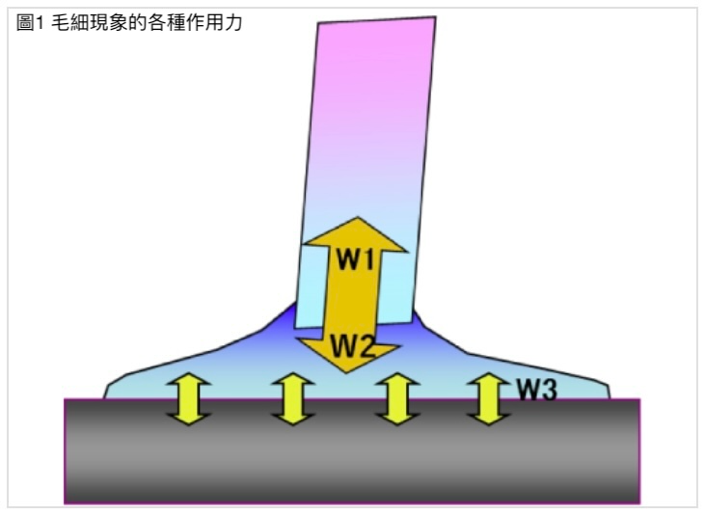

For hydrophilic fiber materials such as cotton or polyvinyl alcohol (PVA)-made artificial suede, the hydroxyl groups present in the structure cause the fiber molecules to have high surface tension, attracting molecules of water and oil through intermolecular forces, drawing these liquids upward. This phenomenon is also known as capillary action.

Capillary action can be roughly explained, as shown in Figure 1, as a tug-of-war between the tension (W1) acting between the inner surface of the capillary and the liquid molecules entering inside, and the gravitational force (W2) acting on the liquid inside the capillary. When the tube is thinner and W2 is smaller, the liquid rises. The ability to remove stains is similar and depends on the balance of three factors: the adhesion force of the stain to the substrate surface (W3), the interaction force between the fiber and the stain (liquid) (W1), and the gravitational force (W2). If W3 is small enough, W1 can relatively take effect, causing the stain components to be attracted to the fiber side, making it easier to remove the stain.

Types and Characteristics of Anti-fouling Fluoropolymer Coatings

Anti-fouling fluoropolymer coatings used to reduce fingerprint adhesion and prevent fouling can be roughly divided into two major types, each with its own characteristics. Below is a brief introduction to their features:

2-1. Silane Coupling Anti-fouling Coatings

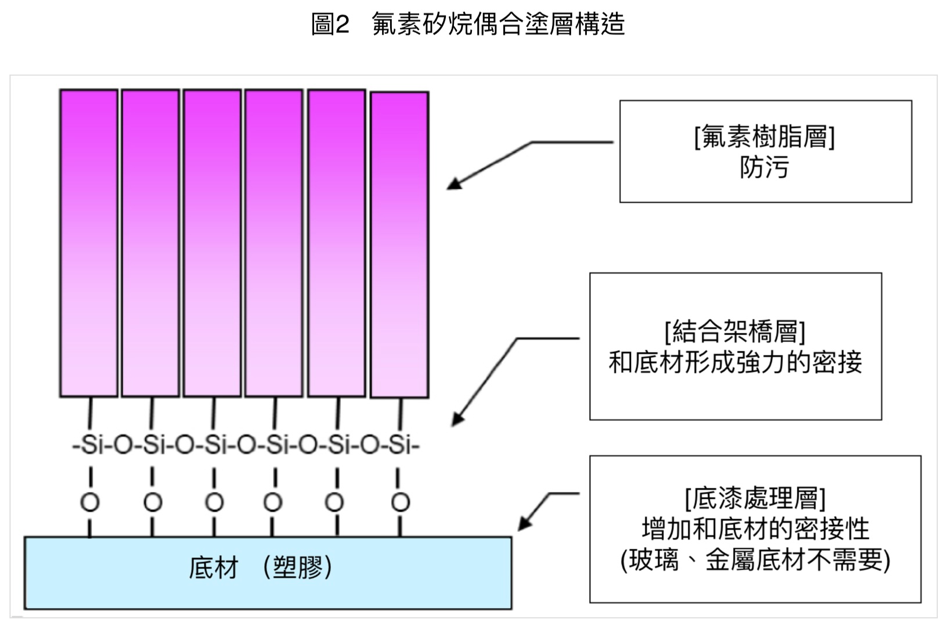

These coatings use fluorosilane coupling agents as coating components. After application, they bond with substrates such as glass and metal through silane coupling reactions, forming a monomolecular fluororesin layer on the surface.

Coatings with this type of bonding have excellent adhesion and abrasion resistance. Additionally, since the thickness of the monomolecular layer is approximately 10-20nm, it is invisible to the naked eye and does not damage the appearance or optical properties of the coated material. Moreover, even if the coating components peel off due to gradual abrasion or aging, this peeling occurs at the molecular level, making it invisible to the naked eye. Therefore, the appearance does not become mottled, nor does it affect the appearance of the coated object.

Furthermore, because it has high adhesion and the coating thickness is insufficient to cause scratching of the coating, it has excellent scratch resistance. From these perspectives, it can be said to be the most suitable coating for preventing fingerprint adhesion. However, if the surface does not have hydroxyl or carboxyl groups, such as with general plastics, this coupling reaction will not occur, and the components will not adhere to each other. In such cases, a pretreatment agent such as polysilazane or tetraalkoxysilane is required to form a silica primer on the substrate surface, followed by the use of anti-fouling coatings to treat the surface.

When these coatings initially appeared on the market, they used perfluoroalkyl (Rf-type) silane coupling agents for the fluororesin layer. Recently, perfluoropolyether (PFPE-type) products have emerged. The water contact angle for Rf-based coatings is 117°, while for PFPE-based coatings, it is 110°. Although the water contact angle for PFPE-based coatings is lower, their actual anti-fouling performance and smoothness are much higher, making PFPE-based products gradually become mainstream.

These coatings can be applied using conventional methods such as spraying or dipping. Due to their molecular weight of approximately 4000, they can also be applied using vacuum deposition methods. Vacuum-deposited coatings are very durable and can be used for fingerprint anti-fouling on eyeglass lenses and touch panels. However, the process cost of this method is high, so cheaper products are gradually shifting towards using more cost-effective wet processes for coating.

2-2. UV-Curable Anti-fouling Coatings

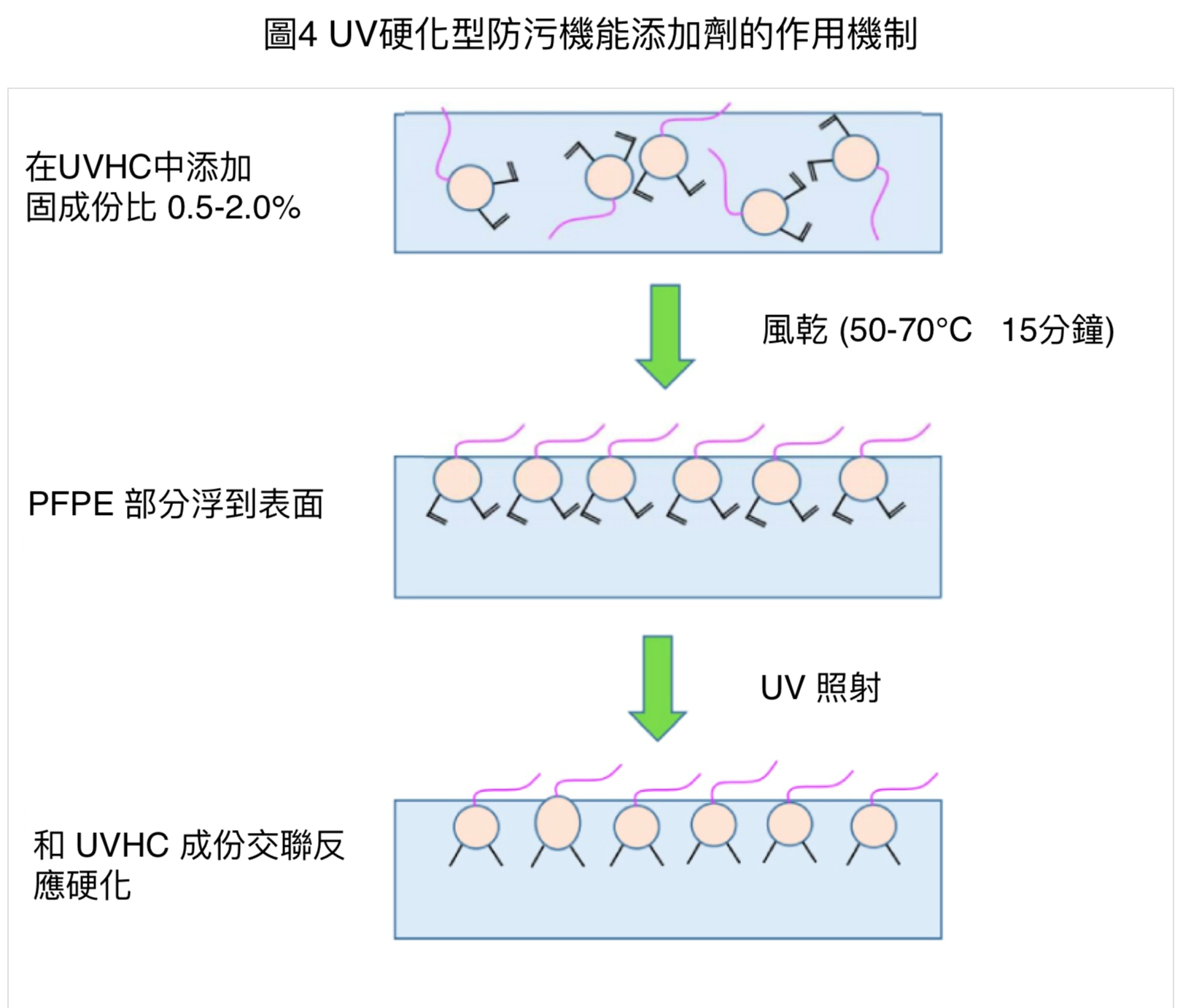

This system has two main types: additive types added to UV-curable resins and paint types that are already mixed with UV-curable resins and photoinitiators and can be used directly. The characteristic of UV final irradiation curing is fast curing speed, suitable for high-speed continuous coating on plastic films such as roll-to-roll.

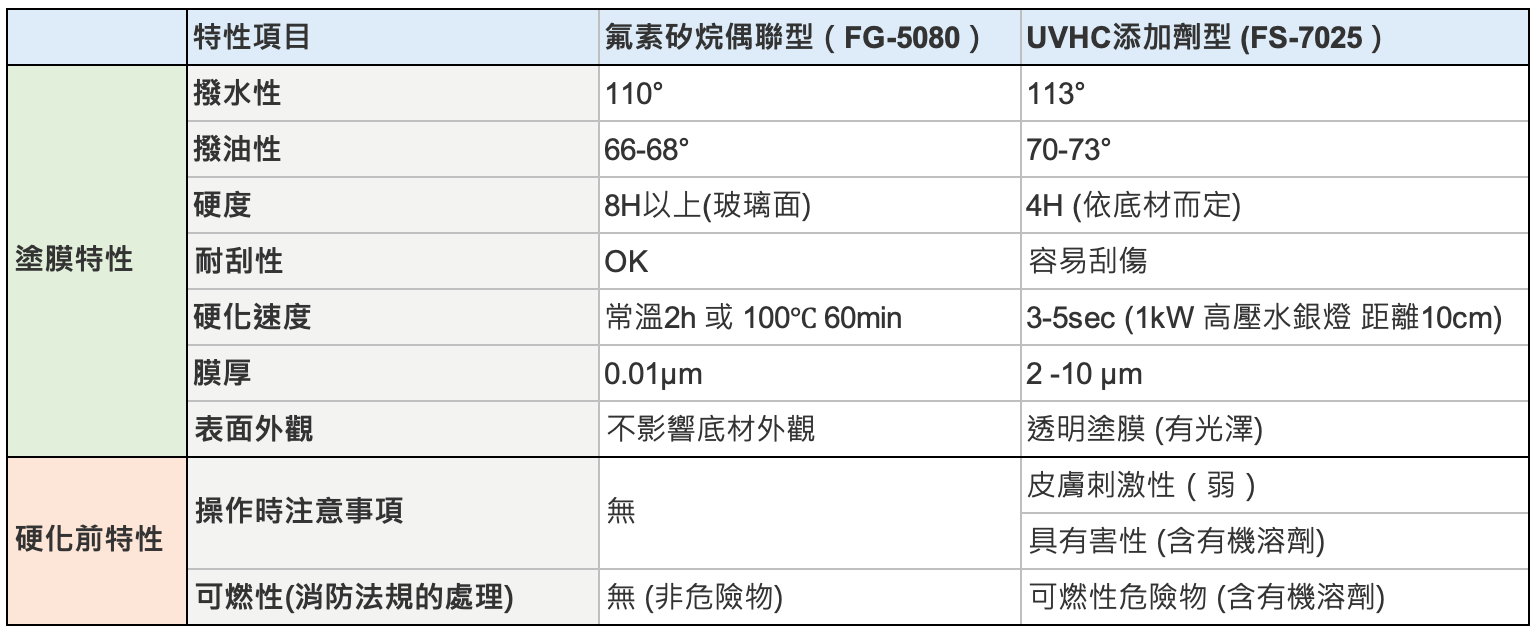

The curing reaction is a crosslinking reaction caused by free radical polymerization, which is inhibited by oxygen. Therefore, it needs to be exposed under nitrogen to isolate oxygen during exposure or make the film thicker under normal conditions. Additionally, the surface appearance after coating has a glossy appearance. During the drying process, the PFPE-based component in the structure floats to the surface, and even a small amount (about 1% solid content) can be effective. Table 2 shows a comparison between the UV-curable anti-fouling coatings we prototyped and the reactive anti-fouling coatings described in the previous section.

Evaluation of Wear Resistance of Fluoropolymer Coatings From the practical perspective of anti-fouling and reducing fingerprint adhesion, the adhesion and durability of materials are often evaluated through friction tests to measure material wear and contact angles. This section will introduce these evaluation methods for anti-fouling coatings.

The scratch test and tape test are commonly used for evaluating the adhesion of coatings. These tests observe the difference in adhesive strength between the tape and the coating, which is influenced by the surface tension of the coating. Therefore, these tests are not suitable for evaluating the adhesion of water-repellent or anti-fouling coatings and will not be discussed here.

3-1. Anti-fouling Performance Evaluation Traditionally, the static contact angles of water or oil have been used as general indicators of anti-fouling performance and reducing fingerprint adhesion. However, some touchscreen manufacturers have recently only evaluated the static contact angle of water when assessing new requirements such as anti-fouling and reducing fingerprint adhesion. However, the static contact angle of water alone cannot effectively assess the removal of sebum stains and the ease of fingerprint removal (reduction in fingerprint adhesion, ease of wiping off fingerprints).

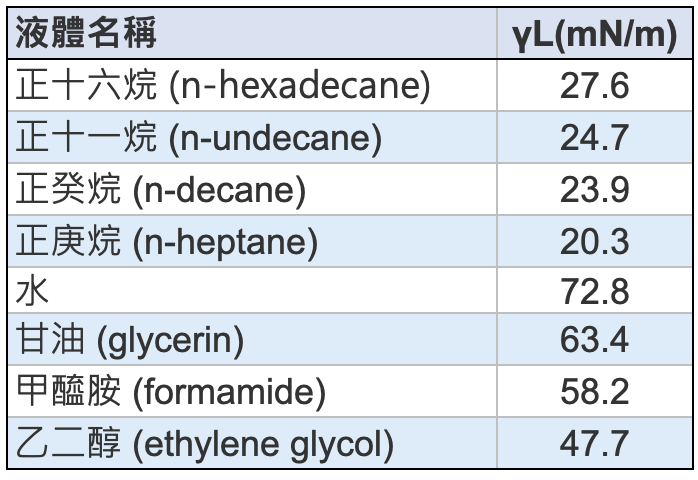

The main component of fingerprints is sebum. If the evaluation is based solely on the static contact angle of water, which has a surface tension relatively higher than that of the components of fingerprints, it cannot effectively evaluate the adhesion of fingerprints. For example, when a surface is coated with a silicon-based compound, the surface tension of the silicon-based compound is 24-30 mN/m (Table 1), so water (72.8 mN/m) can easily achieve a static contact angle of over 100° and be easily repelled. However, it cannot repel the oily components of hexadecane with a similar surface tension (27.6 mN/m) (Table 3).

This illustrates that the surface treated with a silicon-based compound has no effect on preventing fingerprint adhesion, and it can be seen that the static contact angle of water is not a suitable evaluation for reducing fingerprint adhesion. In practical situations, when the anti-fouling coating deteriorates due to wear, it is often found that there is no correlation with the static contact angle.

Table 3: Surface Free Energy of Liquids

For objects used in daily life, the mechanism of fingerprint adhesion always involves movement, so it is necessary to evaluate from the perspective of the adhesion ability of dirt. Therefore, measuring the dynamic contact angle is more appropriate than the static contact angle.

For objects used in daily life, the mechanism of fingerprint adhesion always involves movement, so it is necessary to evaluate from the perspective of the adhesion ability of dirt. Therefore, measuring the dynamic contact angle is more appropriate than the static contact angle.

To evaluate the anti-fingerprint adhesion performance, as mentioned earlier, since the main component of fingerprints is sebum, the evaluation of the oily component is more important than that of water in dynamic contact angle measurement. Generally, substances similar to fingerprint components such as hexadecane, oleic acid, and triglycerides are used for dynamic contact angle measurement. JIS-K2246 also mentions artificial fingerprint fluids, but these are used to evaluate corrosion resistance and are not suitable for evaluating anti-fouling performance.

In addition, when actually measuring the dynamic contact angle, it is often observed that there is a deviation of several degrees in the measurement values. This is due to fluctuations on the surface of the object being measured (wetting of the contact surface and flipping of the polymer) and the surrounding environment (temperature, humidity, airflow, vibration). Therefore, it is best to perform about 5 to 8 measurements on the same sample surface to obtain an average and error.

The official Japanese standard for contact angle measurement can be found in the "JIS R3257 Glass substrate surface wetting test method," which can be viewed and purchased on the website of the Japanese Industrial Research Institute.

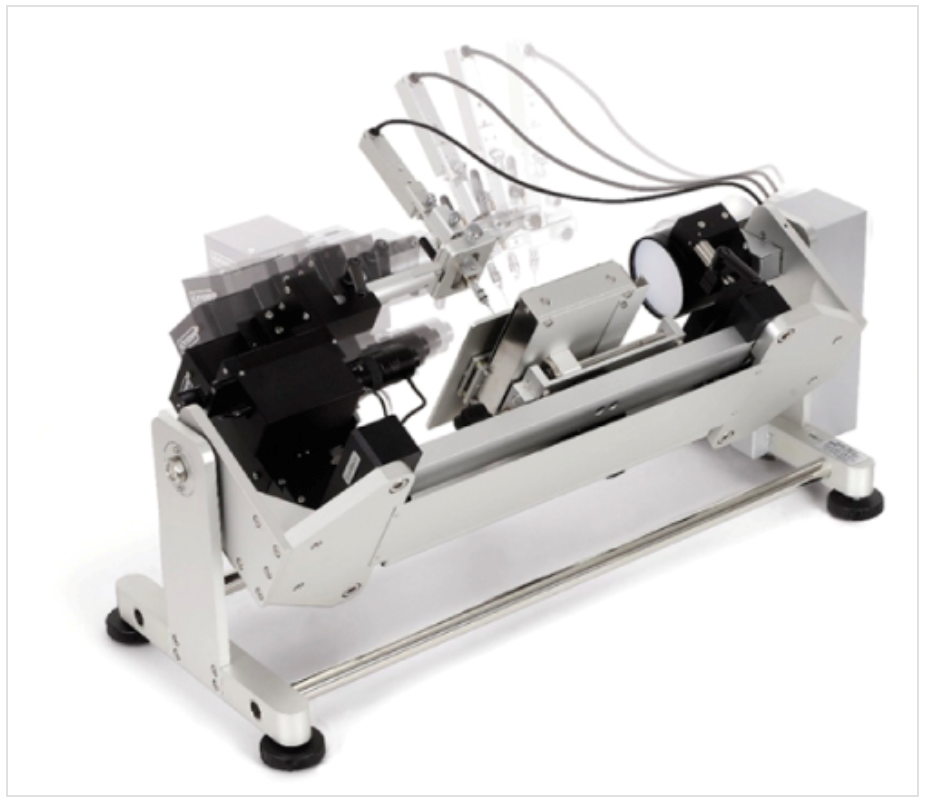

Figure 5: Contact Angle Meter Figure 6: Contact Angle Meter Measurement Screen

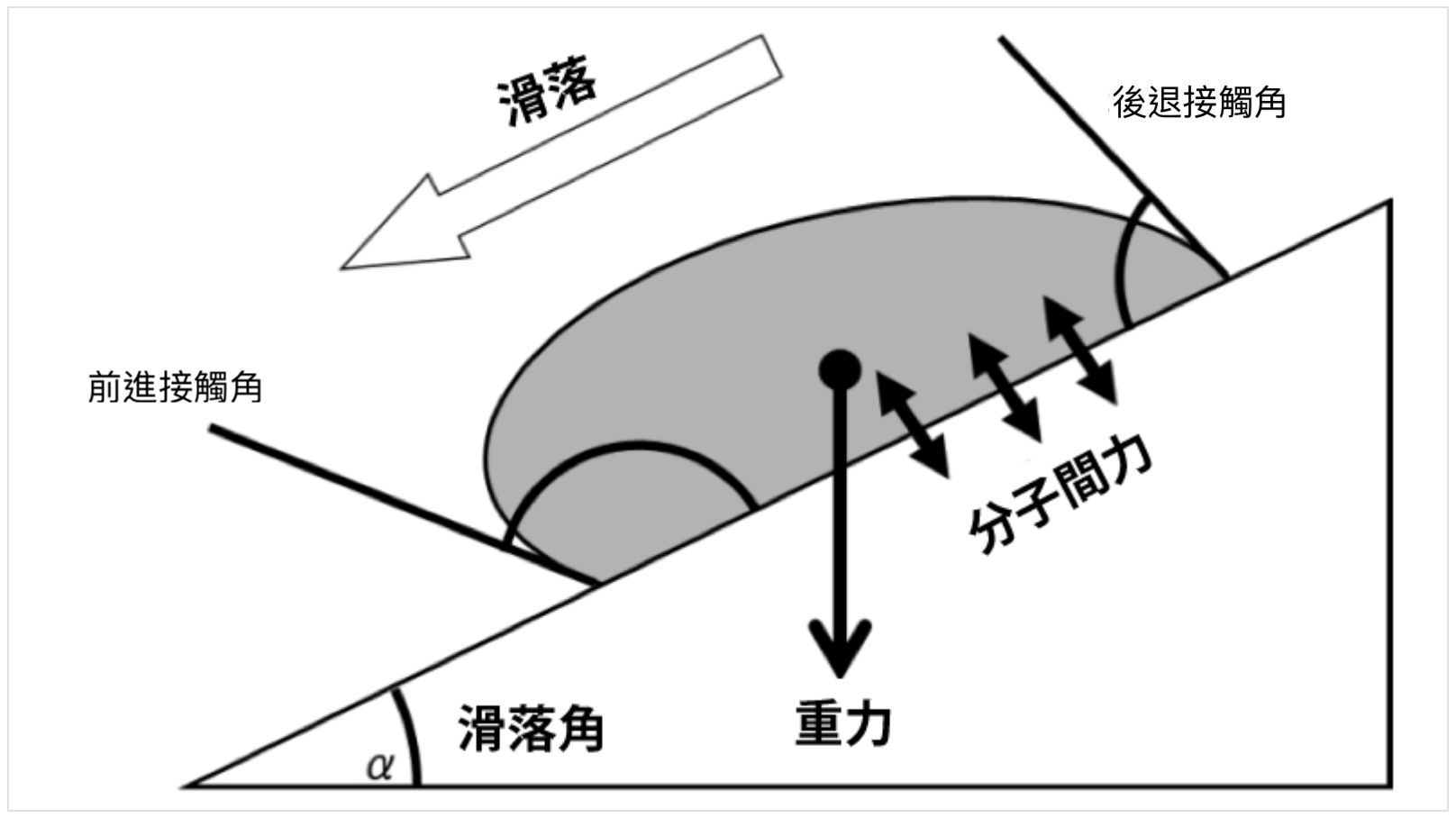

From these three contact angles and the volume of the droplet, the adhesion energy of the droplet on the solid surface can be estimated. The sliding angle and the receding contact angle are highly correlated with fingerprint adhesion. The smaller the sliding angle, the lower the adhesion energy; the larger the receding contact angle, the lower the surface tension. Therefore, if these values perform well, it can be said that their anti-fouling property, especially the fingerprint removal property, is high. Whether the droplet slides off the solid surface depends on the difference between the vector of the force of the liquid adhering to the solid surface and gravity. (Figure 7)

Figure 7: Measurement of dynamic contact angle using the sliding method

To do this, it is necessary to standardize the weight of the droplet being measured. However, currently available contact angle meters on the market do not have mechanisms to maintain a constant weight for the droplet being measured. The contact angle meter mentioned above, which uses the sliding method with image processing for contact angle measurement, has the capability to calculate volume based on the projected area through image processing.

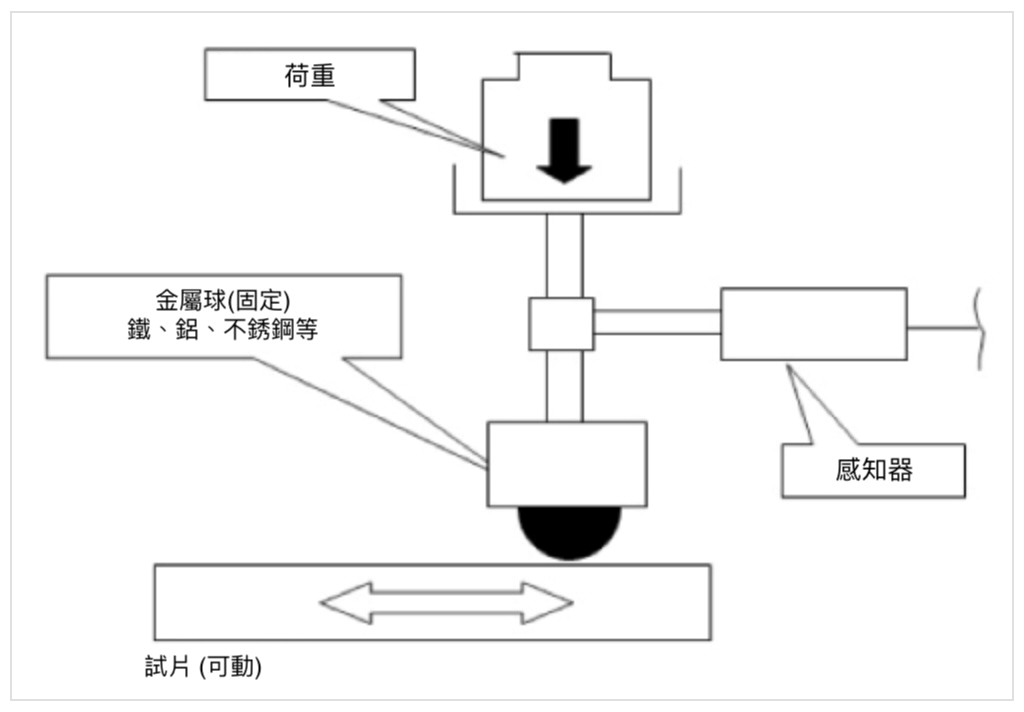

3-2. Evaluation of Wear Resistance The general method for evaluating wear resistance is to use a friction tester to compare the contact angles before and after friction to measure performance. There are two types of friction testers: one measures the friction coefficient through repeated friction (Figure 8), and the other simply applies mechanical friction to degrade the surface of the test piece (Figure 9). The former measures the friction coefficient, making it convenient to determine the remaining condition of the anti-fouling coating based on the change in the friction coefficient.

Figure 8: Friction tester with friction coefficient measurement device Figure 9: Friction tester

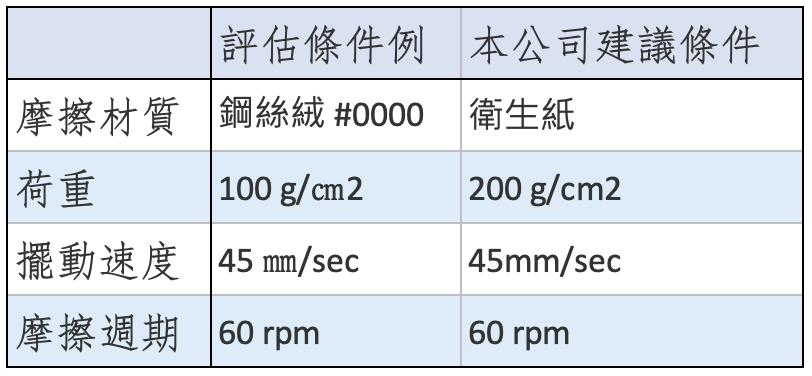

Under these test conditions, the anti-fouling layer and the base material are likely to be scratched by the steel wool. Additionally, based on the aforementioned reasons, it is difficult to accurately assess the degradation of anti-fouling performance based solely on the static contact angle of water.

3-2-2. Our Recommendation We conduct durability friction tests based on customized conditions. (Table-4) Since the most common behavior for cleaning dirt by consumers seems to be using tissues or clothing, we chose tissue paper as the friction material. Under these conditions, the anti-fouling coating components that have adhered to the tissue paper may reattach to the surface of the test piece, reducing the impact of friction on deterioration. To prevent tissue paper damage, it is necessary to replace it every 1,000 cycles. When conducting comparative evaluations, the load can also be set to 1 kg/cm² to shorten the test time.

In our performance evaluation, we use the sliding dynamic contact angle measurement of hexadecane in combination with the simple evaluation method described in the next section to assess the performance of the anti-fouling coating.

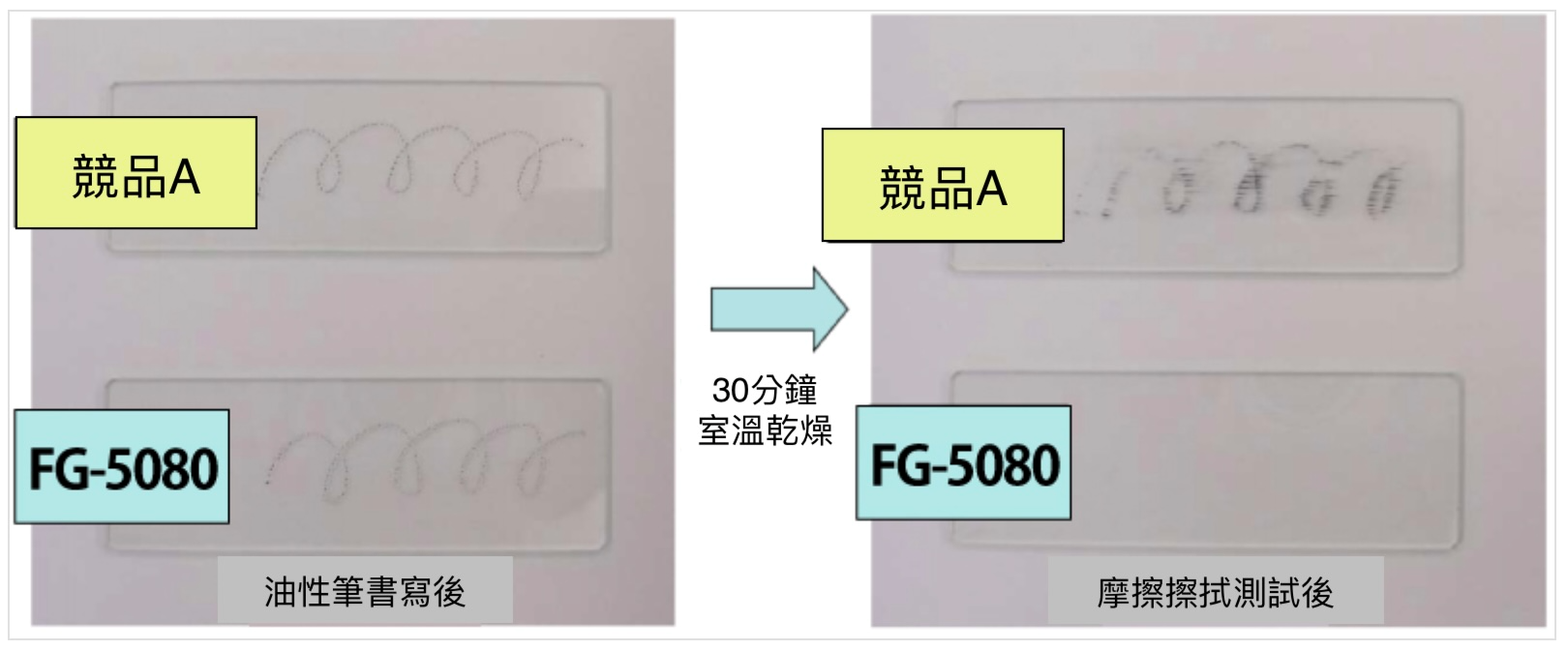

3-2-3. Simple Test Method (Oil-Based Pen Test) Dynamic contact angle meters require high-speed image processing and are quite expensive equipment. The test itself is qualitative. We will introduce a cheap and simple method to evaluate anti-fouling resistance without the need for equipment.

The test is conducted in the following order: (1) Write with an oil-based pen on the anti-fouling film. (2) Let it dry at room temperature for 30 minutes. (3) Wipe the sample with tissue paper using a fixed load (1 kg) (if possible, use a friction tester). (4) Observe the condition of the remaining ink strokes according to the set wiping cycle or count the number of cycles required to completely remove them.

It should be noted that evaluating anti-fouling properties using human fingerprints is quite unstable, as even for the same person, the secretion state (and perhaps composition) can change instantly, making it impossible to obtain an accurate assessment. Here, we use a stable and easily accessible oil-based pen as a substitute for fingerprint components.

Furthermore, it goes without saying that it is best to use the same brand of oil-based pen and tissue paper. Additionally, since the results will vary depending on the drying time, the drying time should also be constant.

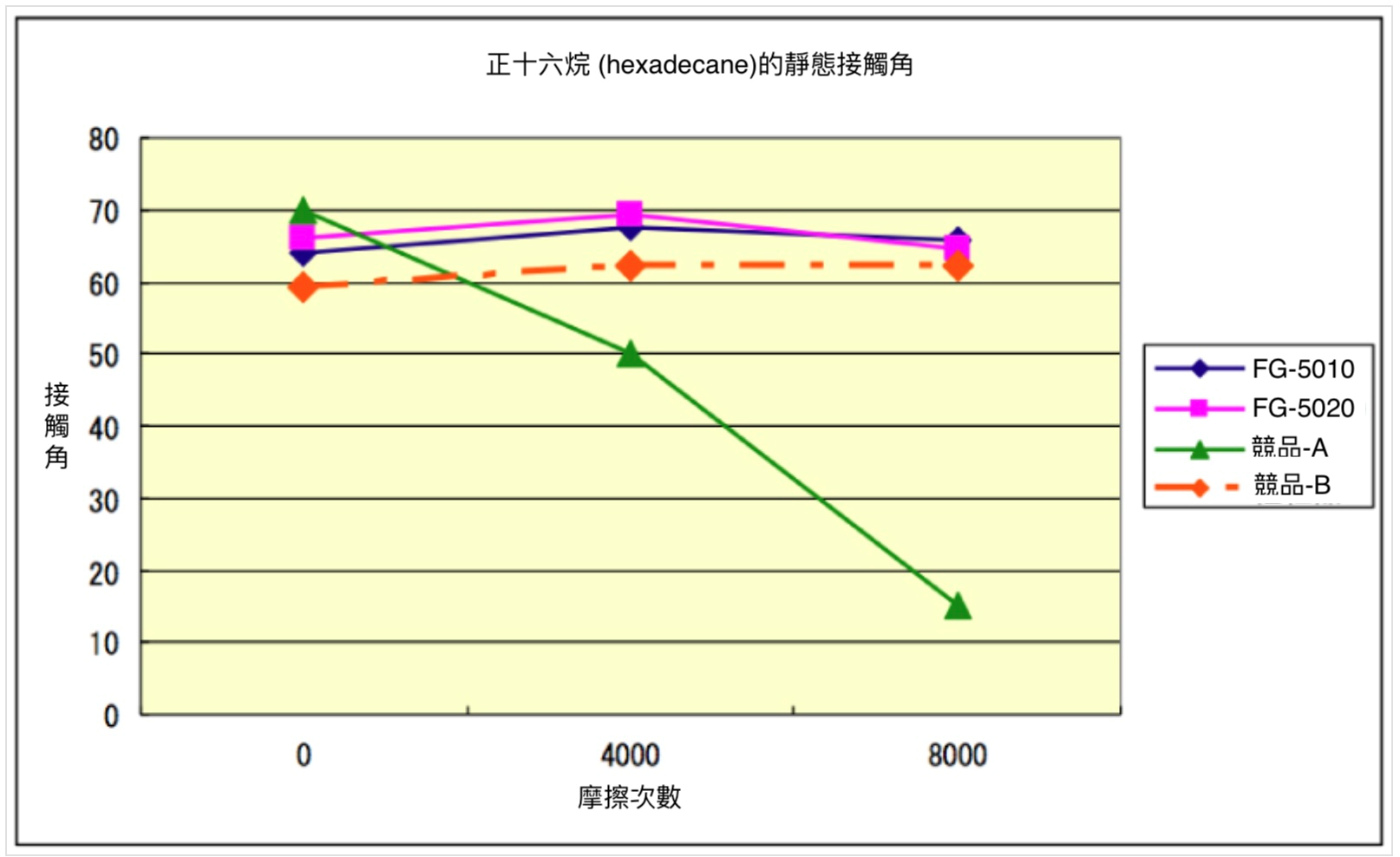

3-3. Actual Evaluation Examples and Their Criteria Here, we will introduce examples of evaluations using the most common sliding dynamic contact angle method with hexadecane.

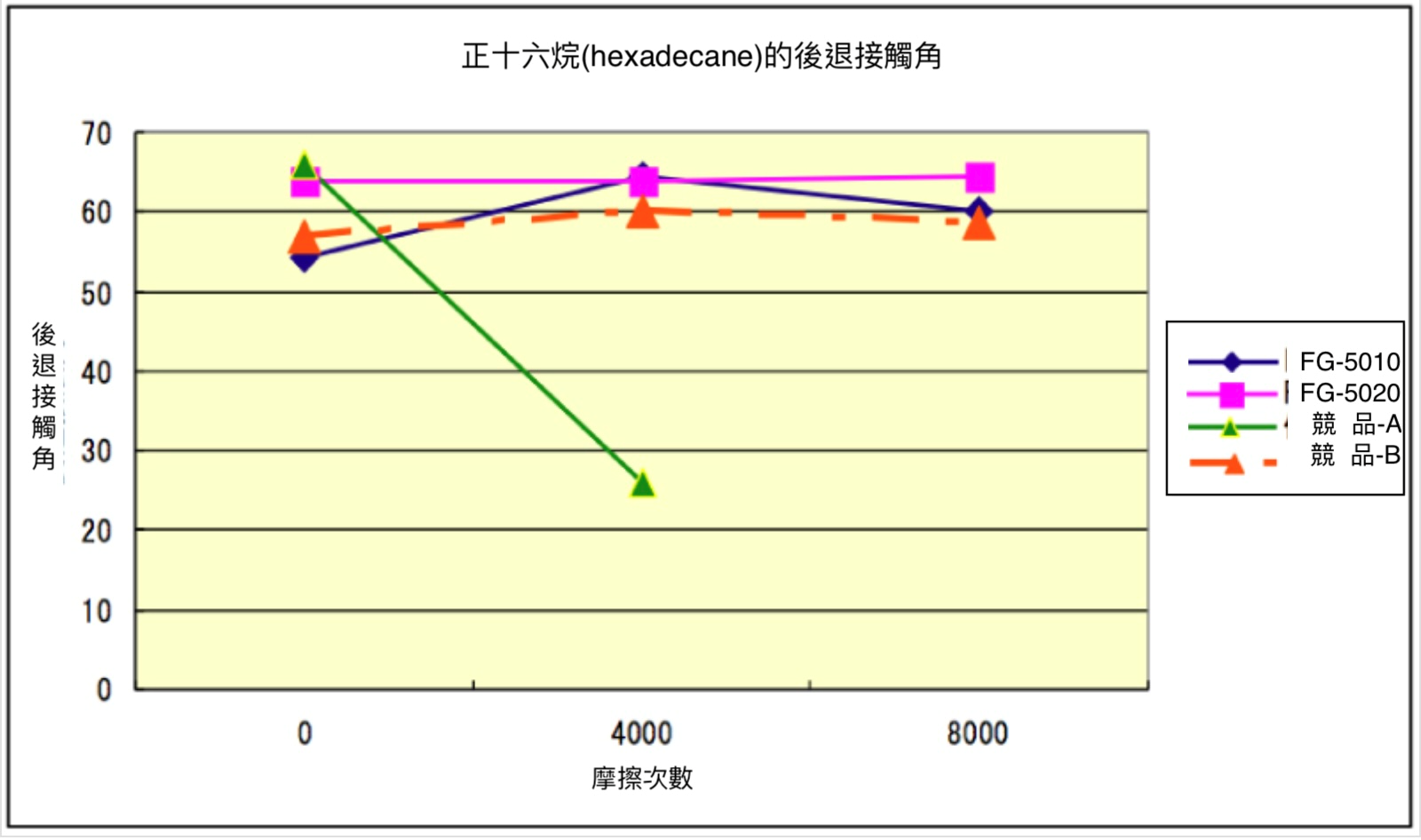

The friction tester mentioned earlier was used to apply frictional damage to our products Fluorosurf FG-5010, FG-5020, Competitor-A, and Competitor-B (Figure 9), and the changes in static contact angle (Figure 10), sliding angle (Figure 11), and receding contact angle were measured (Figure 12). Figure 13 shows a simple evaluation and dynamic contact angle evaluation of the Fluorosurf FG-5080 series of perfluoropolyether (PFPE) type fluoropolymer anti-fouling coatings and perfluoroalkyl (Rf) type fluoropolymer anti-fouling coatings.

These results indicate that the static contact angle is not an indicator of anti-fouling performance, while the dynamic contact angle is correlated with anti-fouling performance.

Figure 10: Oleophobicity - Changes in static contact angle with number of friction cycles Figure 11: Oleophobicity - Changes in sliding angle with number of friction cycles

Figure 12: Changes in Oleophobicity - Receding Contact Angle with Number of Friction Cycles

3-3-3-1. Evaluation Criteria for Contact Angle The evaluation criteria for anti-fouling performance based on contact angle are as follows. If the static contact angle measured with hexadecane is less than 50°, it is difficult to say that it has oil repellency. A smaller slip angle is better; if a slope of about 30° or greater is required, the anti-fouling performance is usually poor. However, as mentioned earlier, the type of test liquid and the size of the droplet can affect the results, so caution is needed. A smaller difference between the receding contact angle and the static contact angle is preferable; if this difference is 10° or greater, the anti-fouling performance is usually poor.

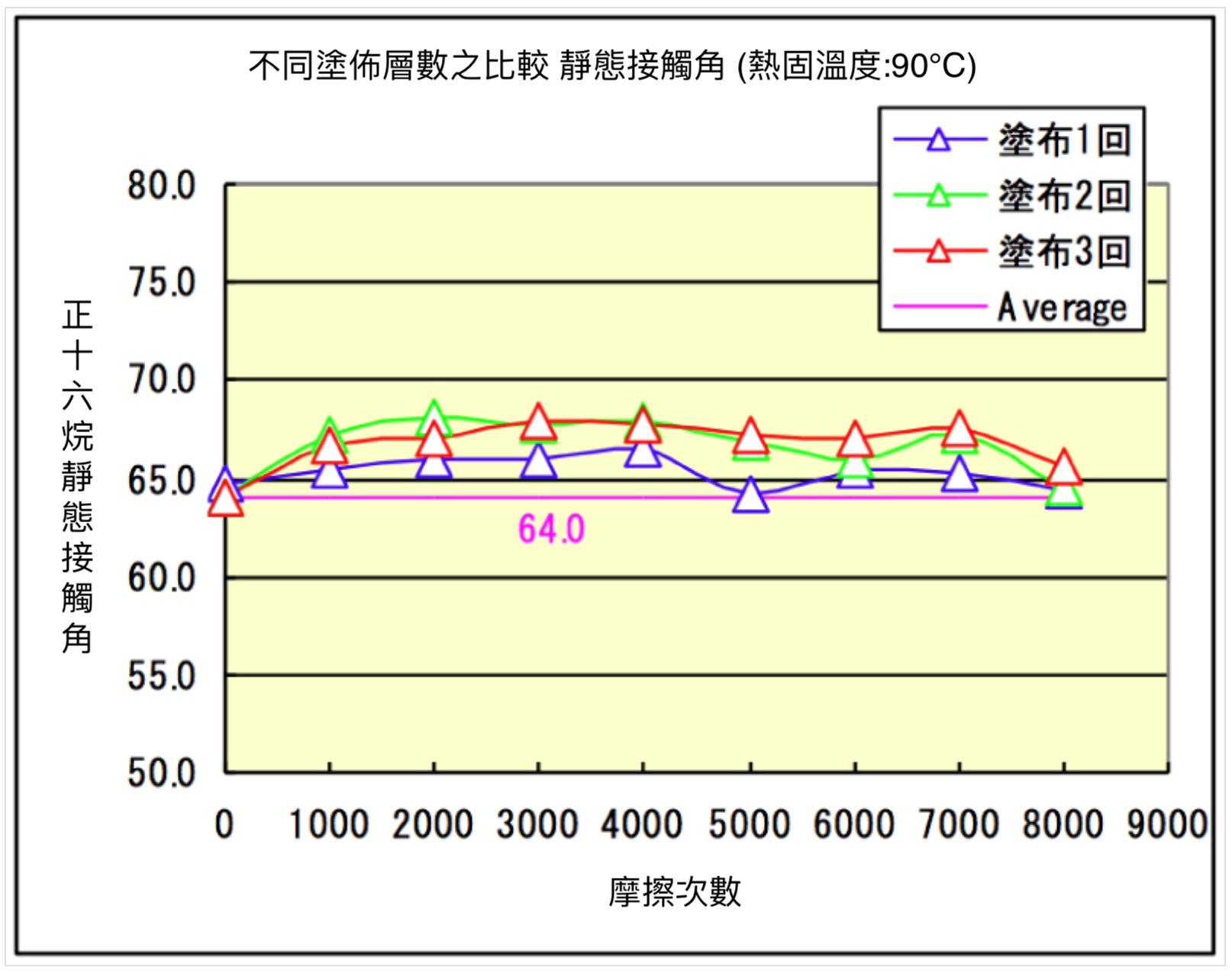

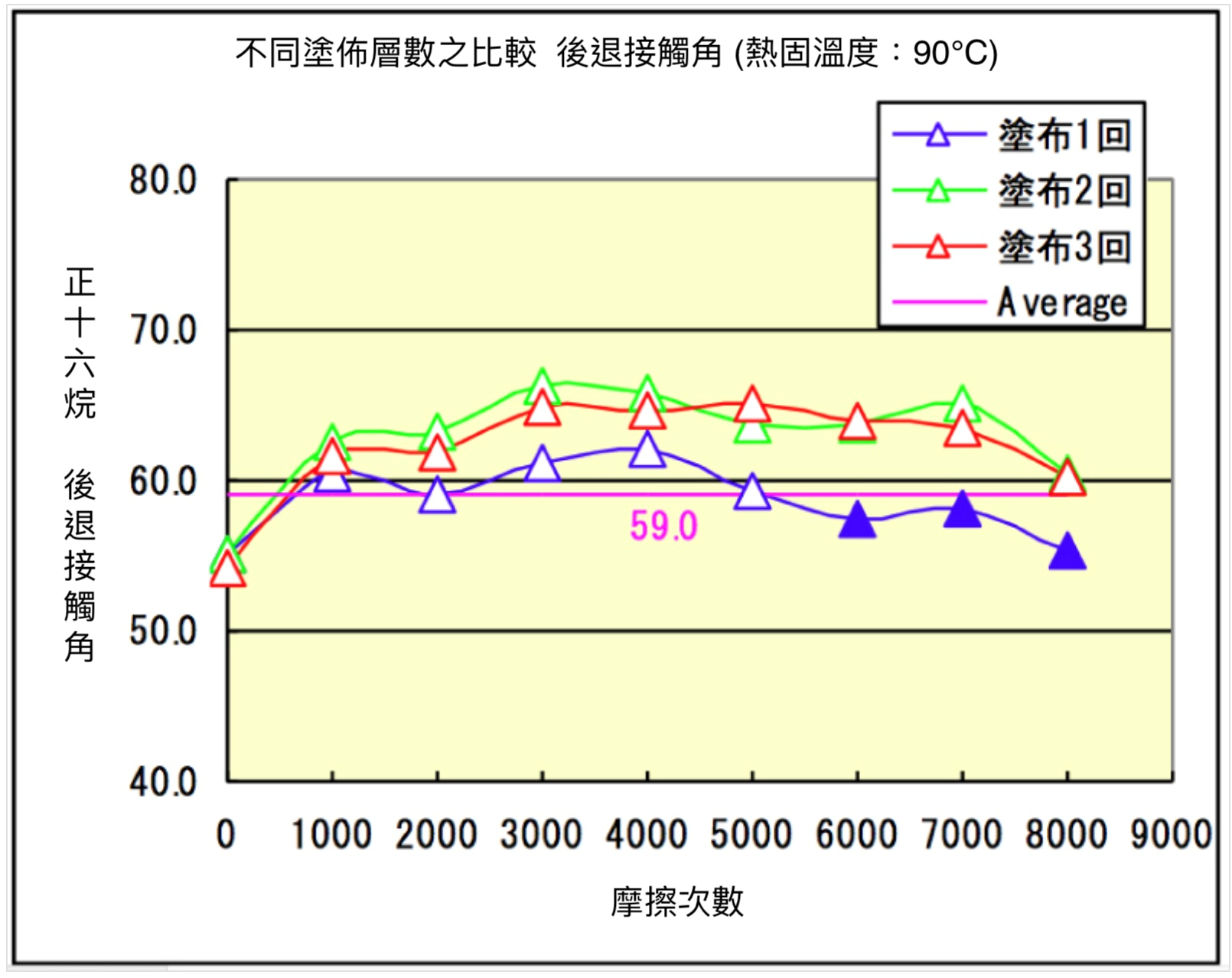

3-3-3-2. Evaluation Criteria for Simple Test Method It is mainly judged based on the amount of residual oil-based ink on the surface; however, if the writing can be clearly drawn with the pen during writing, or if there is still ink residue on the surface after four wipes, it is generally recommended to reject the sample. Techniques for Using Fluorine Anti-Fouling Coating Agents (Silane Coupling Type)Figure 14: Number of Coatings and Oil Repellency (Static Contact Angle) Currently, for fingerprint and anti-fouling on touch screens of smartphones and other devices, silane coupling type coating agents are used, and the initial performance and durability may be affected by the coating method and drying conditions during wet process coating. This section introduces techniques for achieving correct performance during wet process coating.

4-1. Coating Method The anti-fouling performance and durability of these fluorine coating agents are generally considered to be influenced by the density of the active ingredients of the coating agent and the substrate surface. Figures 14 to 16 show the durability data of the dynamic contact angle of hexadecane oil repellency when using a multi-layer coating by immersion method.

In the above example, there is not much difference in the static contact angle (Figure 14), but both the sliding angle (Figure 15) and the receding contact angle (Figure 16), which are important indicators of anti-soiling performance, improve with an increase in the number of coating layers. This is likely because multiple coating layers allow more active ingredients to adhere to the surface.

Additionally, if good initial performance is not achieved, it often occurs due to either insufficient or excessive coating amounts.

Insufficient coating amounts result in the fluororesin layer not completely covering the coated surface (Figure 17), allowing dirt to be adsorbed through the uncovered gaps via intermolecular forces, leading to poorer dirt removal performance. This can be observed in dynamic contact angle measurements through an increase in the sliding angle.

Regarding deterioration after friction, the molecular units of the coating components peel off from the surface, causing the fluororesin layer to become sparse, similar to the condition with insufficient coating amounts. As a result, both dirt removal performance and sliding angle are affected.

Excessive coating amounts result in unreacted coating agent components remaining on the coating layer without binding to the surface. (Figure 17) These unreacted coating agent components have residual alkoxysilane groups that form a hydrophilic surface, increasing the surface tension and affecting the contact angle. However, these excess components are unbound free components, so they are removed during actual use, leaving only the components bound to the surface. Therefore, the original performance can still be obtained after some time of use. (Figure 20) The data obtained after 1,000 friction cycles is better than the initial value for this reason.

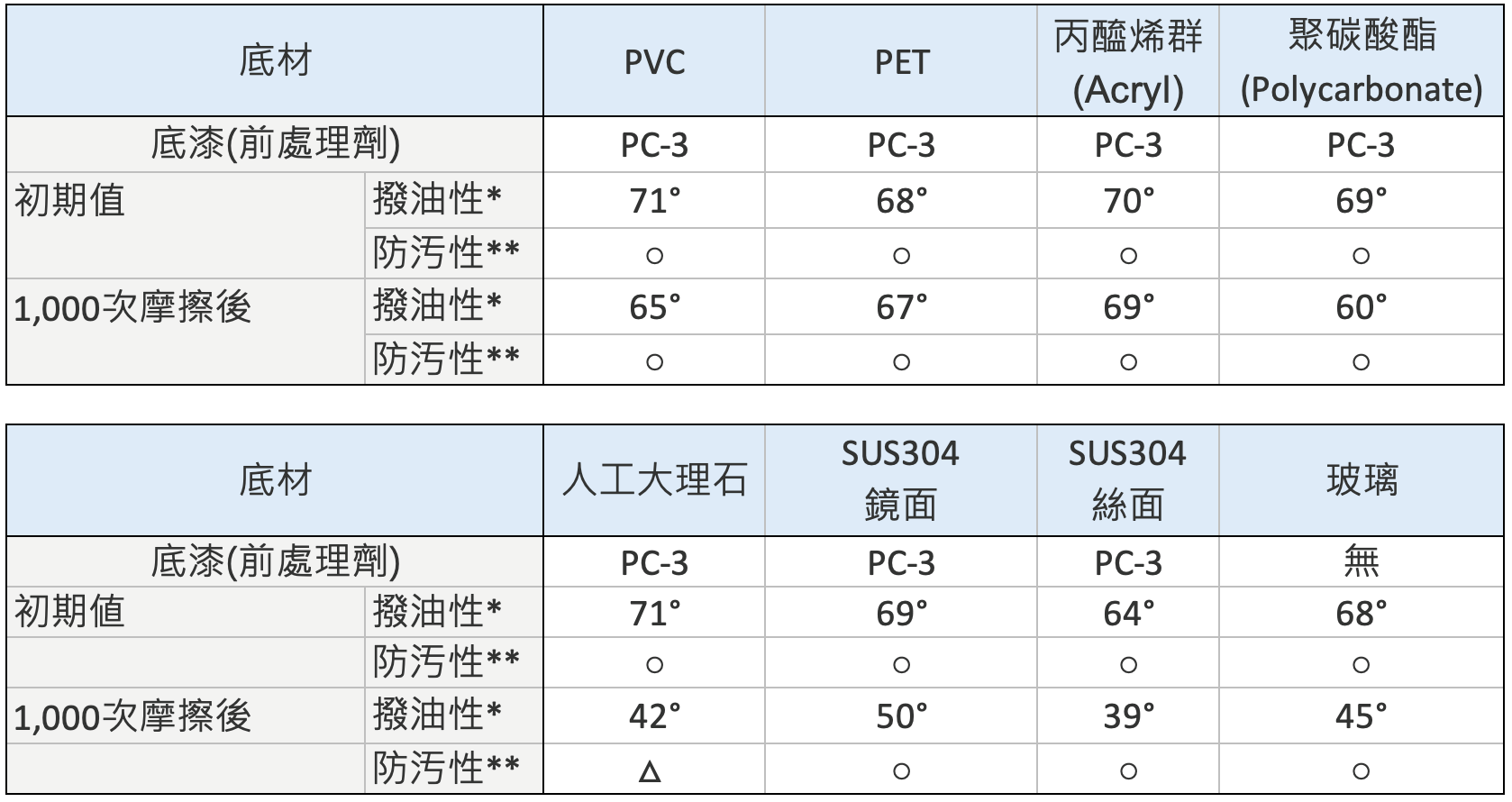

Drying Method Silane coupling type anti-soiling coatings, like other silane coupling agents, react with moisture and acidic components in the air to promote silane coupling with the substrate. Although this reaction also occurs at room temperature, heating the product to 70°C to 120°C can accelerate the reaction and generally improve anti-soiling and durability. (Tables 5 and 6)

Table-5 After 24 hours of drying at room temperature for Fluorosurf FG-5010 Table-6 After drying with heating for Fluorosurf FG-5010

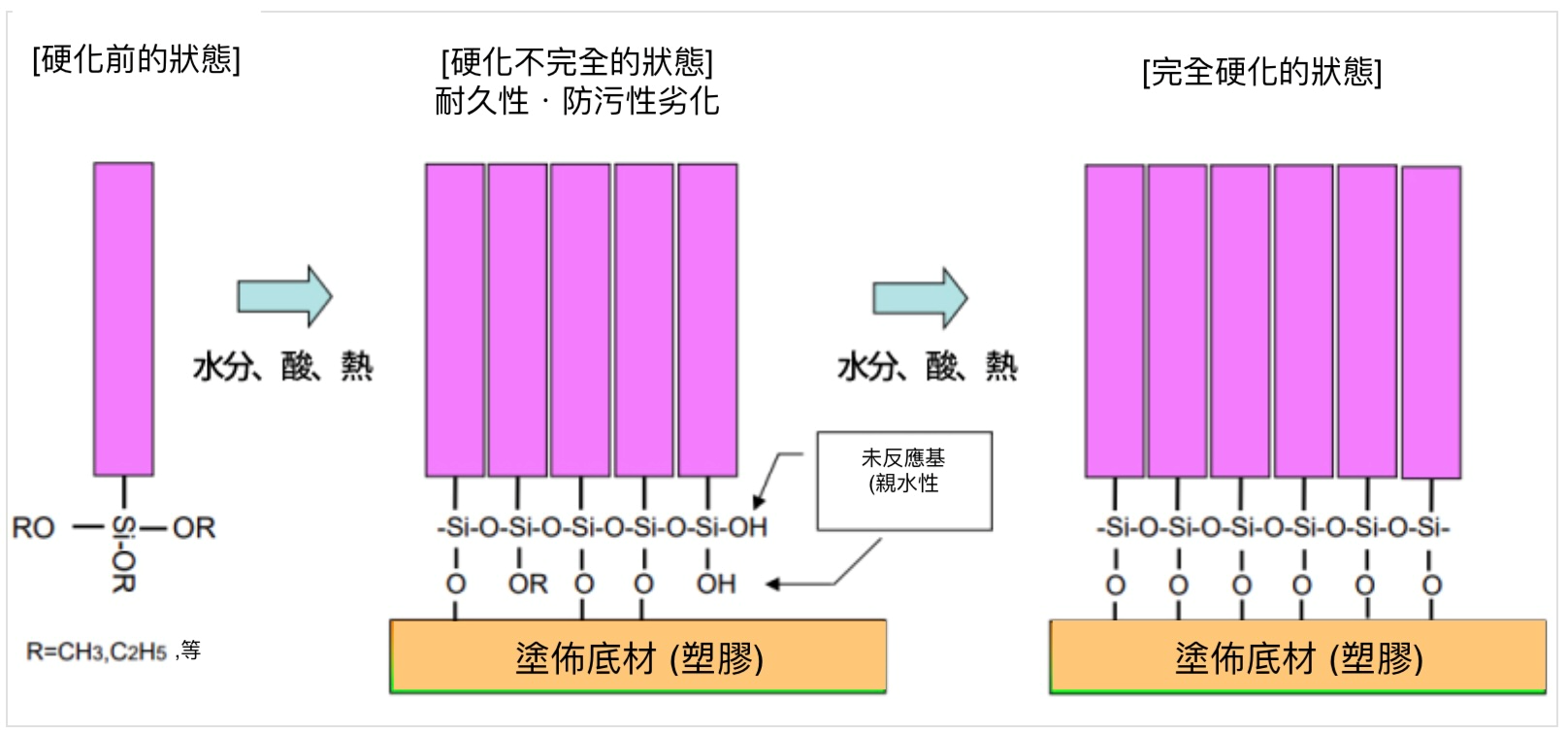

(Figure-18) Illustrates the curing process of silane coupling-type coatings. Insufficient curing is believed to increase surface tension due to the residual hydrophilic groups such as alkoxy and silanol.

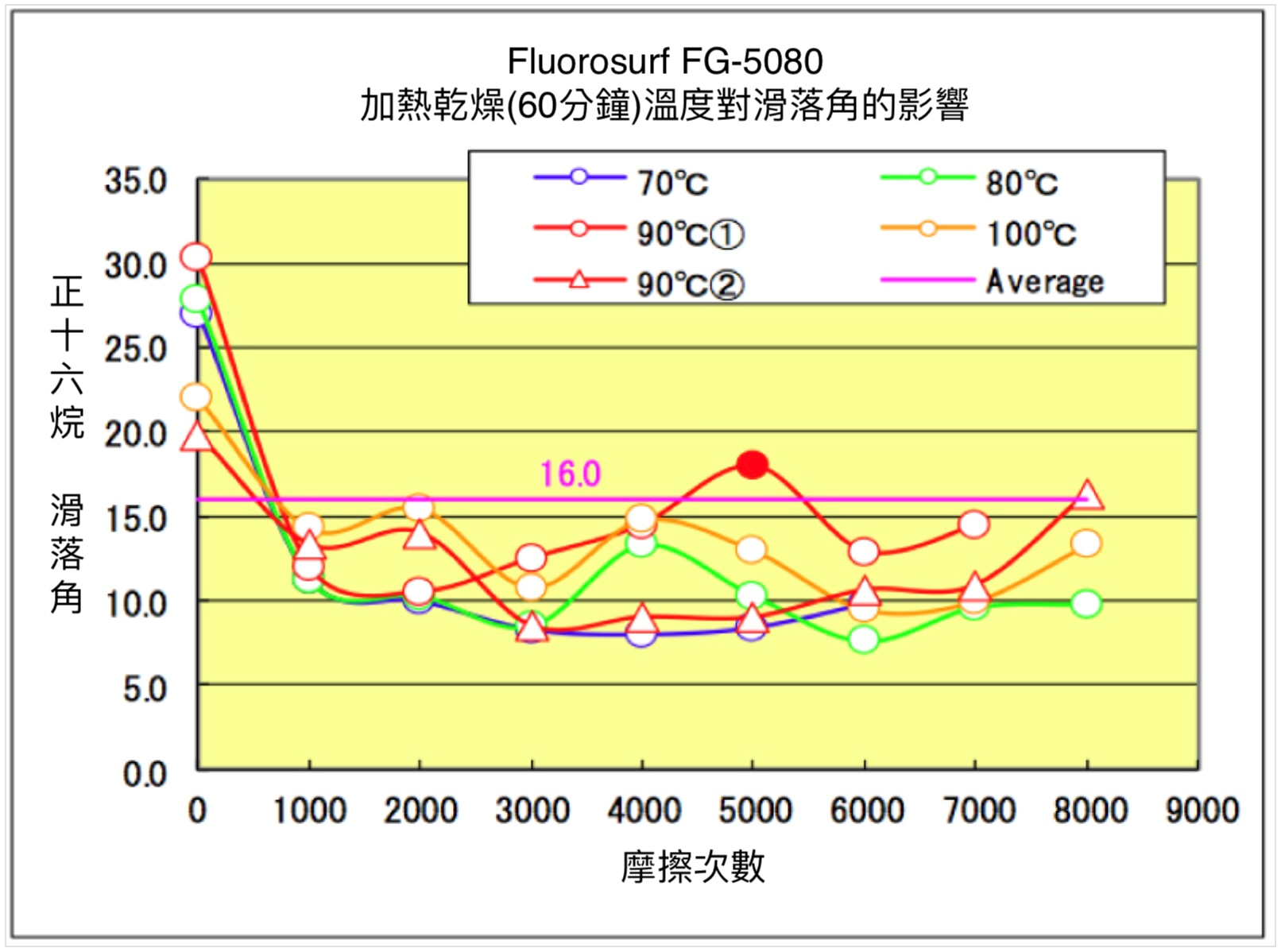

In (Table-5) and (Table-6), the reason why the heating-dried group performed slightly better than the room temperature dried group is presumed to be due to the difference caused by these unbound groups. Additionally, the reduced bonding quantity leading to insufficient adhesion also resulted in slight differences in abrasion resistance. (圖-19) to (圖-21) depict the dynamic contact angle graphs of Fluorosurf FG-5080 at different drying temperatures and its oil repellency durability. It can be observed that those dried at higher temperatures generally exhibit better durability. This may be due to the reduction in the number of residual unreacted groups caused by heating.

Figure-18: Curing process of silane coupling-type anti-fouling coatings Figure-19: Drying temperature and oil repellency (static contact angle)

Figure-20: Drying temperature and oil repellency (sliding angle) Figure-21: Drying temperature and oil repellency (receding contact angle)

For plastics, it is important to consider the temperature resistance of the coating material; however, the conclusion is that within the allowable range, completing curing through heating drying is important for achieving good anti-soiling performance.

3-3-3. Evaluation criteria Evaluation criteria vary depending on the application of the product and the quality standards of the user. Below, we will discuss some typical standards."

Currently, there is no official standard for the volume of the test liquid. Since each company conducts measurements based on its own liquid volume standards, comparing only the values of the sliding angle is meaningless. For reference, the values actually measured by our company are: liquid temperature 25℃, water 25μl, hexadecane 5μl.